In today’s fast-paced industrial landscape, waste management isn’t just about disposal — it’s about recovery, savings, and sustainability. One of the smartest decisions a factory can make is conducting regular scrap audits with a focus on the growing role of Scrap Recycling Industries.

Whether you manage a manufacturing plant, a power generation facility, or a distribution hub, knowing exactly what you’re throwing away (and how much it’s worth) can transform your bottom line. Let’s dive into why scrap audits are essential and how they align with the goals of the modern recycling ecosystem.

What Is a Scrap Audit?

A scrap audit is a systematic review of all the waste, damaged parts, and unused materials being discarded during industrial processes. The goal is simple: identify what’s being wasted, how often, and what value can be recovered.

It goes beyond just cost-cutting. A good scrap audit helps companies:

- Reduce material loss

- Improve process efficiency

- Ensure regulatory compliance

- Maximize return on recyclable materials

And when done in coordination with expert Scrap Recycling Industries, the results are even more impressive.

Why Factories Must Prioritize Scrap Audits

1. Reduce Operational Waste and Save Money

Factories often overlook the hidden costs of daily material loss. Metals, wires, and broken equipment can quietly pile up, costing thousands in unrecovered assets.

With proper scrap audits, companies can partner with Scrap Recycling Industries to turn that waste into cash, contributing to both short- and long-term savings. In some cases, recovered scrap becomes a new revenue stream — not just cost recovery.

2. Boost Environmental Responsibility

Incorporating audits into your operations means you’re also contributing to industrial sustainability. When your waste materials — such as industrial scrap metal or old transformers — are properly tracked and routed through professional recycling channels, you’re actively minimizing landfill usage and environmental harm.

By working with specialized Scrap Recycling Industries, you ensure waste is handled in compliance with eco-friendly standards.

What Can Be Recovered Through Scrap Audits?

A scrap audit often uncovers a variety of valuable recyclable materials:

- Industrial scrap metal like aluminum, copper, and steel

- Obsolete scrap wire and cables

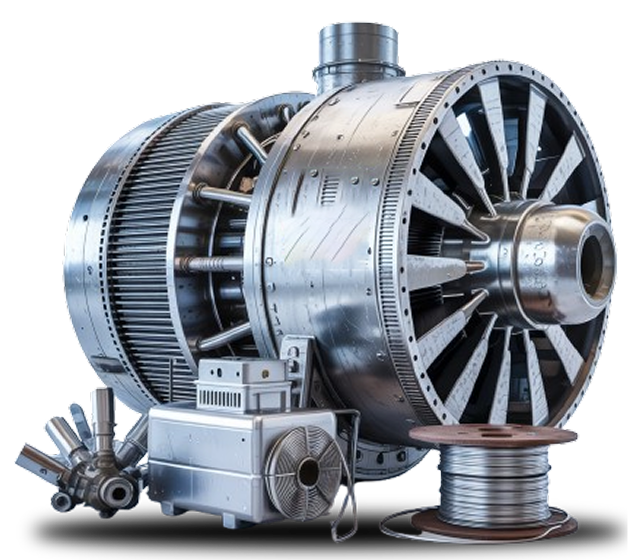

- Decommissioned scrap equipment and machines

- Outdated or damaged transformers

- General industrial scrap

Even materials previously deemed “worthless” can become valuable when handed over to experienced scrap equipment buyers who specialize in asset recovery.

The Role of Scrap Recycling Industries in This Process

Scrap Recycling Industries are more than just recyclers — they’re strategic partners. These industries don’t just pick up junk; they help businesses optimize disposal, identify reclaimable assets, and even provide value assessments on recyclable inventory.

With the right scrap buyer, you can:

- Determine scrap transformer prices

- Find buyers for industrial recycling equipment

- Coordinate transformer dismantling projects

- Plan industrial disposal or demolition disposal

- Leverage efficient industrial dismantling strategies

Benefits of Partnering with Professional Scrap Buyers

Here’s what factories gain when they work with certified Scrap Recycling Industries:

- Fair market rates: Get paid competitive prices for your recyclables

- Convenient logistics: From pickup to dismantling, they manage it all

- Regulatory compliance: Meet local and national waste management standards

- Transparent reporting: Data on what was recycled, how much, and its value

These partnerships make sure you’re not leaving money — or compliance — on the table.

Common Audit Mistakes to Avoid

Even if you’re conducting scrap audits, you may not be getting full value if you:

- Don’t work with experienced industrial recycling partners

- Fail to separate valuable scrap (e.g., copper from general waste)

- Ignore periodic re-evaluation of recyclable materials

- Don’t calculate or document recovery savings

A strong partnership with Scrap Recycling Industries will help avoid these mistakes and bring long-term operational improvement.

Conclusion: Scrap Audits Are No Longer Optional

In a competitive industrial economy, every piece of material, every ounce of metal, and every broken part matters. Scrap audits allow factories to gain control of waste streams, uncover lost value, and boost sustainability.

When aligned with trusted Scrap Recycling Industries, these audits become more than a compliance tool — they become a competitive advantage.

Factories that invest in scrap auditing and recycling partnerships today are the ones that will lead in efficiency, profitability, and environmental responsibility tomorrow.