When it comes to large-scale demolition, few projects are as complex or as critical as dismantling power plants and factories. These facilities contain heavy machinery, valuable components, and potentially hazardous materials, all of which must be managed with expertise and precision. At JJ Liquidations, we specialize in managing the entire lifecycle of industrial teardown, from industrial dismantling to demolition disposal, and the resale or recycling of recovered equipment.

1. Initial Assessment and Planning

The first phase of a demolition project involves a thorough site assessment. Engineers and project managers evaluate the structure’s design, the condition of machinery, and the presence of hazardous materials like asbestos or chemicals. This stage is crucial for mapping out a safe, efficient dismantling process and determining which components have resale or recycling value.

At JJ Liquidations, our team conducts detailed evaluations and offers quick, competitive quotes for scrap and machinery, ensuring clients maximize the value of their assets from the start.

2. Power Plant Dismantling and Equipment Recovery

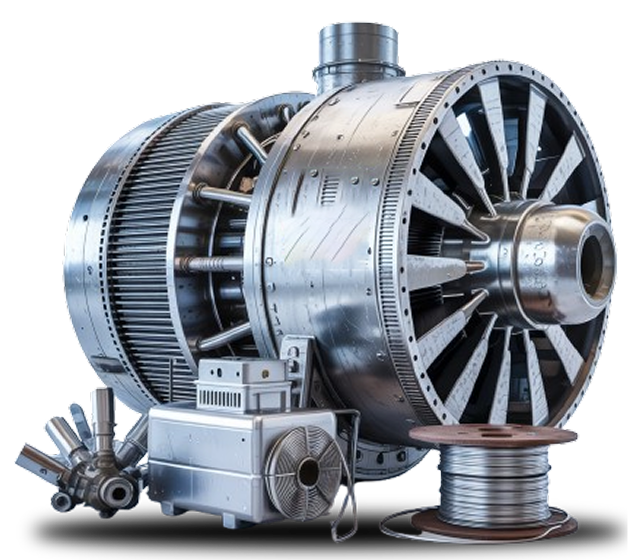

Once a plan is in place, the industrial dismantling begins. This process includes the careful deconstruction of equipment such as boilers, generators, turbines, switchgear, and more. Heavy equipment must be removed without damaging valuable components or endangering workers.

Our crew is trained in the safe extraction of high-value parts like gas turbines, which we often purchase as part of our asset recovery program. We also specialize in turbine recycling, where obsolete or damaged turbines are processed for their recyclable materials.

3. Scrap Segregation and Recycling

As machinery is dismantled, metal components are sorted by type—steel, copper, aluminum, and more. These materials are then processed and sold as industrial metal scrap, a critical revenue source during factory or plant demolition.

JJ Liquidations is one of the top industrial scrap buyers in the USA. Our streamlined process allows us to quickly appraise and purchase scrap from any job site, helping clients reduce downtime and cleanup costs.

4. Demolition Disposal

After salvageable materials and equipment are removed, what remains is demolished using controlled methods such as implosion or mechanical dismantling. The rubble is then managed through environmentally responsible demolition disposal practices, ensuring all waste is properly removed and recycled where possible.

We work in compliance with all federal and state regulations, offering clients peace of mind that every demolition is handled professionally and legally.

5. Final Site Clearance and Restoration

Once demolition is complete, our crew performs final clearance of debris, and if required, prepares the land for new development. This end-to-end approach ensures your site is ready for its next phase—whether that’s rebuilding, repurposing, or selling.

Why Choose JJ Liquidations?

JJ Liquidations is a trusted partner in the demolition and recycling industry. With years of experience in managing high-value equipment and handling complex demolition projects, we’ve built a reputation for efficiency, safety, and competitive payouts.

Whether you’re planning a full plant teardown or need help with turbine recycling or industrial metal scrap sales, we’re here to help every step of the way.