When it’s time to upgrade or decommission an old Commercial HVAC system, proper removal is critical to ensure safety, compliance, and cost-efficiency. Whether you’re managing a plant shutdown or upgrading your facility’s cooling systems, the process of HVAC unit removal must follow structured industrial dismantling protocols. At JJ Liquidations, we specialize in complex machinery removal and are recognized as one of the Top industrial scrap buyers in the USA. Here’s a look at the step-by-step process of commercial HVAC unit removal—and how we can help streamline it.

Step 1: Evaluation and Site Assessment

Before any removal begins, our team conducts a thorough evaluation of Commercial HVAC system and the surrounding infrastructure. This includes:

- Inspecting the unit’s size, type, and location

- Identifying any hazardous materials, like refrigerants or asbestos

- Planning the safest removal strategy to avoid disruption to ongoing operations

This preparatory phase ensures that the demolition disposal is handled with environmental responsibility and full regulatory compliance. We integrate this planning phase with broader power plant demolition services when working in large-scale facilities.

Step 2: Disconnecting Utilities

All electrical, gas, and coolant lines connected to the Commercial HVAC unit must be safely disconnected. Our trained professionals carefully depressurize the system, remove refrigerants according to EPA guidelines, and ensure that all power sources are isolated to prevent accidents during removal.

Step 3: Industrial Dismantling of the Unit

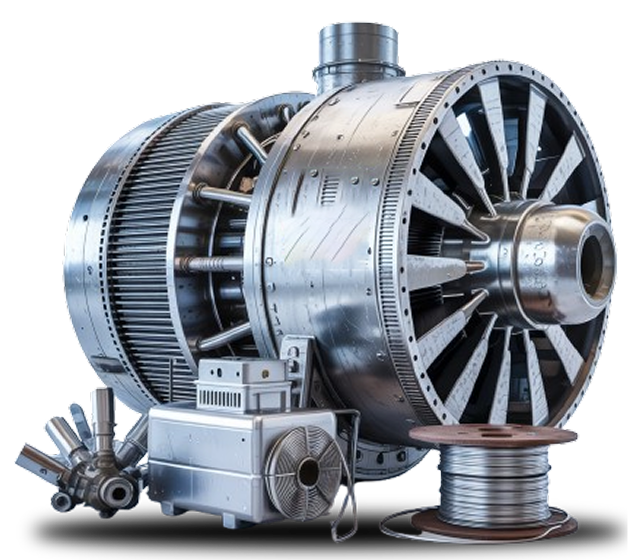

Once utilities are disconnected, we begin the physical dismantling of the HVAC unit. This includes:

- Unbolting and disassembling major components

- Cutting structural supports if necessary

- Handling heavy equipment with cranes or forklifts

JJ Liquidations follows strict safety protocols during every industrial dismantling project to protect workers and the facility.

Step 4: Sorting and Recycling of Components

Many HVAC units contain valuable metals, electronic parts, and recyclable materials. We sort components such as:

- Compressors

- Motors

- Copper tubing

- Steel frameworks

These are categorized and prepared for recycling or resale. Our expertise in industrial metal scrap enables us to extract maximum value from these parts, giving businesses an opportunity to recoup a portion of their initial investment.

Step 5: Turbine and Equipment Recycling

For facilities with integrated systems that include turbines or other large-scale electrical components, we also offer turbine recycling as part of the HVAC removal process. Our specialists are experienced in decommissioning turbine-driven chillers and energy recovery units commonly used in industrial cooling systems.

Step 6: Final Disposal and Site Clean-Up

After all salvageable parts have been removed and sorted, the remaining debris is processed for responsible demolition disposal. We ensure that non-recyclable materials are discarded in compliance with local and federal environmental standards. Once disposal is complete, the site is cleaned and prepped for future use or renovation.

Why Choose JJ Liquidations?

At JJ Liquidations, we bring decades of experience to every job. From standalone HVAC units to entire facility cleanouts, we handle complex projects with professionalism and efficiency. As one of the Top industrial scrap buyers in the USA, we offer:

- Fast on-site evaluations

- Competitive payouts for scrap and salvageable equipment

- Safe, compliant, and efficient removal services

- Full transparency throughout the removal and recycling process

If you’re planning an HVAC unit removal, plant demolition, or equipment liquidation, trust the experts at JJ Liquidations.