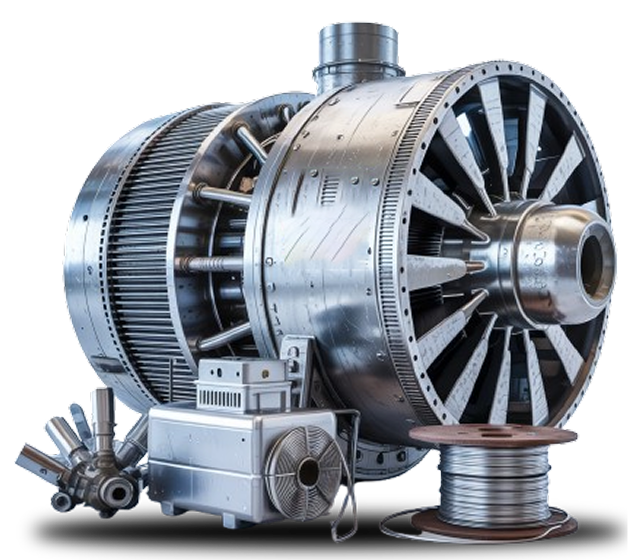

When it comes to removing and recycling scrap machinery, precision, safety, and value recovery are essential. At JJ Liquidation, we specialize in evaluating and managing scrap machinery removal projects from power plants, manufacturing facilities, warehouses, and more. Whether it’s outdated turbines, obsolete generators, or large-scale electrical equipment, our team applies a comprehensive process to ensure maximum value and environmental responsibility.

Step 1: On-Site Assessment and Equipment Identification

Our evaluation process begins with a thorough on-site inspection. This allows our experts to assess the size, condition, and resale or scrap potential of the machinery. From gas turbines to electrical control panels, we determine whether components are suitable for resale or if they should be processed through our industrial recycling network.

We also consider the type of material—ferrous or non-ferrous—and note specific components like scrap wire and copper coils that may command higher payouts. These early insights allow us to give clients a fast and fair quote.

Step 2: Material Recovery and Market Value Analysis

Once we catalog the machinery and materials, JJ Liquidation performs a detailed market analysis. We factor in current transformer recycling prices and commodity rates for metals to calculate the total recoverable value. This is where our expertise as one of the top industrial scrap buyers in the USA comes into play.

We also consider resale opportunities for intact machinery or parts that are still in demand. When resale is possible, it can significantly boost the overall value of the removal project.

Step 3: Environmental Compliance and Safety Planning

Safety and environmental compliance are critical in all our scrap machinery removal jobs. As part of the scrap recycling industries we serve, we make sure that all processes align with federal and local environmental regulations. Our commitment to responsible disposal extends to industrial scrap metal recycling, which is handled through our electrical equipment recycling programs.

Before any dismantling begins, we create a safety plan that outlines equipment handling, transportation routes, and hazardous material management (such as oil-filled transformers or gas-powered systems).

Step 4: Efficient Dismantling and Logistics

JJ Liquidation coordinates the entire dismantling and removal process, minimizing downtime and disruption for your facility. Our crews are trained to handle complex, large-scale operations and use state-of-the-art equipment to safely remove heavy machinery. We also offer scrap wire removal as part of our value-added services, maximizing the return for your project.

Every load is weighed, logged, and documented—ensuring transparency throughout the project.

Step 5: Fair and Fast Payouts

Once the equipment is removed and processed, we offer fast, competitive payouts. Thanks to our extensive buyer network and knowledge of transformer recycling prices, we can guarantee top dollar for your assets. Our goal is to make the entire experience seamless—from evaluation to payment.

Whether you’re decommissioning a factory or clearing space for upgrades, JJ Liquidation provides a turnkey solution backed by years of experience in the industrial recycling and scrap recycling industries.

Why Choose JJ Liquidation?

JJ Liquidation is your trusted partner for industrial scrap metal recycling and machinery removal. With decades of expertise and a reputation for integrity, we help businesses across the U.S. recover value from obsolete or surplus equipment. From scrap wire to complete power systems, we handle it all.

Start your evaluation today—get in touch with the top industrial scrap buyers in the USA and experience fast, transparent service with the best returns in the industry.