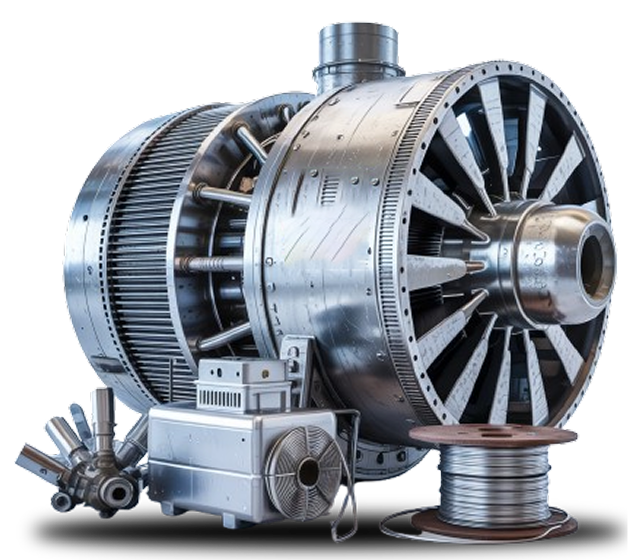

Turbine Parts a critical role in the power generation and industrial sectors, but like any complex machinery, they have a finite operational lifespan. When gas or steam turbines are decommissioned, the components often exhibit a range of mechanical and environmental issues. Understanding these issues not only helps in assessing salvage value but also provides critical insights for those involved in industrial scrap recycling and asset recovery.

At JJ Liquidations, we specialize in evaluating and purchasing decommissioned Turbine Parts and other industrial scrap metal. Below, we outline the most common issues found in these parts and why it matters to the recycling and resale markets.

1. Corrosion and Oxidation

One of the most prevalent issues in decommissioned turbine components is corrosion. Exposure to moisture, chemicals, and high temperatures leads to oxidation—especially on blades, casings, and piping. Corroded parts often lose structural integrity, reducing their salvage value for reuse but increasing their worth in industrial metal scrap markets.

2. Fatigue Cracks

High rotational speeds and repeated thermal cycles lead to fatigue in Turbine Parts and rotors. These microcracks can propagate over time, posing serious safety risks if reused. While these parts may not be suitable for refurbishment, they remain valuable as scrap to metal scrap buyers in the USA like JJ Liquidations.

3. Erosion from Particulates

Turbines operating in dusty or unfiltered environments often suffer from erosion. Abrasive particles cause pitting and wear on blades, vanes, and seals. While severely eroded parts may be unsalvageable, they are often excellent candidates for industrial scrap recycling due to their high alloy content.

4. Thermal Damage and Warping

Prolonged exposure to extreme heat causes some turbine components—especially those near the combustion chamber—to warp or distort. These structural issues render parts unfit for repair but increase their demand in industrial scrap buying due to their high-temperature metal composition.

5. Contamination and Oil Residue

Decommissioned turbines often contain residual oil, grease, and other contaminants that complicate the recycling process. However, at JJ Liquidations, we have the tools and expertise to safely extract and process these materials while maximizing their value in the industrial scrap metal stream.

Why This Matters for Scrap Buyers

For those in the business of turbine disposal or facility decommissioning, identifying these issues early helps determine whether parts should be repaired, resold, or recycled. As one of the best scrap buyers in the USA, JJ Liquidations offers expert evaluations and fast payment for damaged and surplus turbine equipment.

Work With the Turbine Parts

At JJ Liquidations, we’re more than just metal scrap buyers in the USA. We’re trusted partners to energy companies, demolition contractors, and industrial plant managers across the country. Whether you’re liquidating turbine systems or looking to offload obsolete machinery, we’re here to help.

Explore our services:

Contact us today for a fast quote and see why JJ Liquidations is known as one of the top industrial scrap buyers in the USA.