Demolishing a chemical plant is no small task — it’s a high-risk operation governed by strict regulations to protect the environment, workers, and surrounding communities. If you’re planning or managing a chemical plant demolition, understanding the legal framework is not just smart — it’s essential.

At JJ Liquidations, we’ve handled numerous industrial liquidations and demolition projects. Our experience ensures compliance, safety, and maximum recovery of industrial scrap metal. But before any heavy equipment comes into play, here’s what you need to know about demolition regulations.

1. Environmental Compliance Comes First

Chemical plants store and process hazardous materials. Demolition without a thorough decontamination plan can release dangerous substances into the air, soil, and water. Regulatory bodies like the EPA (Environmental Protection Agency) require pre-demolition site assessments and a remediation plan.

Common environmental requirements include:

- Removal of hazardous chemicals and residues.

- Soil and groundwater testing.

- Asbestos and PCB (Polychlorinated Biphenyl) abatement.

2. Permits Are Mandatory — No Exceptions

Demolition permits are required at the federal, state, and often local levels. Failure to secure the appropriate permissions can result in hefty fines, legal action, and project delays.

You’ll likely need:

- Demolition permit

- Hazardous waste handling permit

- Air quality control permit (especially for dust and emissions)

- Water discharge permit (if runoff is possible)

3. OSHA Regulations Protect Workers

The Occupational Safety and Health Administration (OSHA) enforces regulations on demolition safety. These rules cover:

- Safe handling of chemicals

- Fall protection

- Machinery safety

- Confined space entry procedures

- Emergency response planning

Even experienced contractors must conduct safety audits and have documented protocols.

4. Scrap Recovery Must Follow Disposal Laws

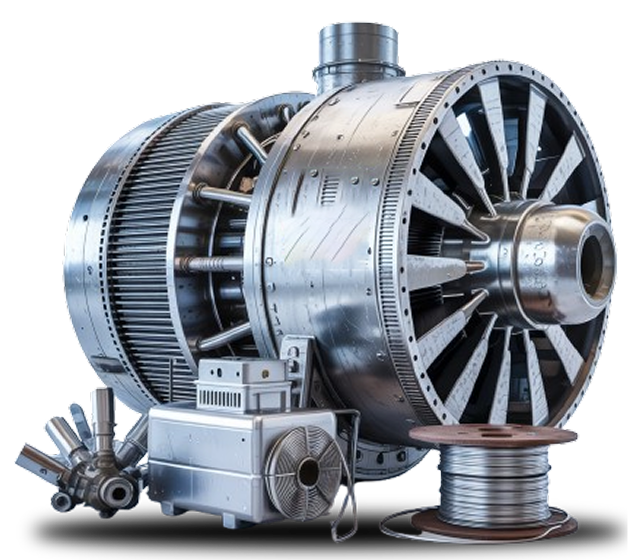

One of the most valuable parts of any demolition is scrap recovery — and chemical plants are full of recyclable metal. However, not all scrap is immediately safe to remove or sell. Materials contaminated with hazardous substances must be properly treated.

JJ Liquidations specializes in industrial scrap recycling and ensures all recovered materials meet environmental standards before being repurposed. Whether you’re dealing with piping, electrical panels, or turbines, we handle everything with regulatory compliance in mind.

Explore our industrial scrap recycling services to learn more.

5. Documentation Is Legally Required

Every step of your demolition project — from initial survey to waste disposal — must be thoroughly documented. Regulatory agencies may audit your processes even after project completion.

You’ll need to maintain:

- Waste manifests

- Air monitoring reports

- Safety inspection logs

- Recycling certificates

Partnering with experienced metal scrap buyers in USA like JJ Liquidations ensures that all documentation is handled efficiently and professionally.

Why Work With Certified Scrap Buyers?

Choosing the right demolition and recycling partner can save time, reduce liability, and maximize asset recovery. JJ Liquidations is among the top industrial scrap buyers in USA for a reason:

We handle industrial metal scrap with safety and compliance.

We offer competitive payouts for high-value industrial assets.

We manage full plant dismantling and scrap processing.

Whether you’re looking for the best scrap buyers in USA or need expert support for demolition logistics, we’re here to help.

Final Thoughts

Chemical plant demolitions are legally complex and environmentally sensitive. Ignoring regulations can result in costly consequences — both financially and legally.

With JJ Liquidations, you’re not just working with scrap buyers — you’re partnering with experienced professionals who understand compliance, logistics, and value recovery from end to end.

Get in touch today for a free evaluation of your demolition project or to learn more about our industrial scrap buying services.