In the ever-evolving landscape of manufacturing and heavy industry, one constant remains — the need to upgrade, downsize, or replace industrial equipment. Whether you’re shutting down a plant, modernizing machinery, or liquidating surplus assets, knowing how to evaluate used industrial equipment for resale is key to recovering value. This is where industrial equipment recycling comes into play — helping businesses minimize waste while maximizing return on old assets.

Before discarding outdated machinery, there’s a lot you can do to determine whether it’s better to resell, recycle, or scrap it. In this guide, we’ll walk you through a practical approach to evaluating equipment, understanding its market potential, and making informed decisions.

Step 1: Assess Operational Condition

The first and most important factor is the operational status of your equipment. If the machinery still works, even partially, it may have resale value in secondary markets or developing regions.

Evaluate:

- Functionality – Can it operate safely and efficiently?

- Physical wear – Look for corrosion, missing parts, or significant damage.

- Maintenance history – Regular service records can increase buyer confidence.

Working equipment may find a new home through auctions or equipment buyers, while non-working units might be better suited for industrial equipment recycling.

Step 2: Check for Market Demand

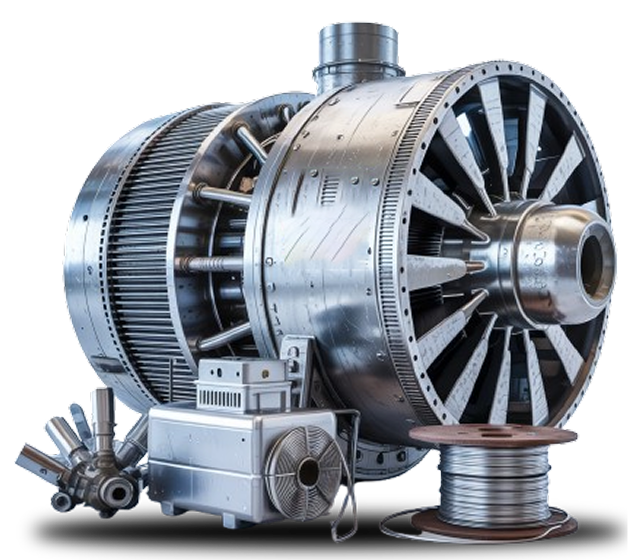

Once the equipment’s condition is clear, research whether there’s current market demand. Certain types of machinery — such as CNC machines, conveyor belts, or transformers — hold consistent value due to industrial demand.

Use online platforms, auctions, and resale marketplaces to check similar listings. If you’re unsure of the demand, connecting with scrap equipment buyers can give you real-time insights into what’s selling and what’s not.

In some cases, even obsolete machines can be sold for parts, making them valuable to dismantlers and refurbishers.

Step 3: Consider Scrap and Material Value

If resale isn’t an option, the equipment might still be worth a considerable amount in raw materials. Industrial equipment often contains metals like:

- Copper

- Aluminum

- Stainless steel

- Steel and cast iron

Selling this equipment as scrap can yield competitive returns. This is where partnering with professionals who specialize in industrial scrap metal becomes crucial. They can evaluate your equipment, break it down efficiently, and ensure you get paid for the metal value inside.

Especially in large facilities, a single outdated transformer or turbine can contain hundreds of pounds of recyclable metal — making industrial equipment recycling both environmentally and financially beneficial.

Step 4: Factor in Transportation and Logistics

The size, weight, and location of your industrial equipment play a major role in determining its value for resale or recycling.

Important factors include:

- Can it be moved easily?

- Will it need to be disassembled first?

- Are there on-site dismantling or pickup services available?

If transport costs outweigh the resale value, recycling locally with experienced industrial recycling providers may offer the best return. Some recyclers offer full-service pickup and decommissioning, which reduces your burden significantly.

Step 5: Work with Certified Buyers or Recyclers

One of the most important steps is choosing the right buyer or recycler. The industrial recycling industry is regulated, and working with certified professionals ensures that your materials are handled responsibly and legally.

Seek out companies that specialize in large-scale industrial cleanouts and understand the specific value of used machinery. For instance, equipment related to the power industry may require expertise in transformer dismantling due to safety and environmental considerations.

Reliable professionals will not only offer fair pricing but can also help you avoid legal or environmental pitfalls.

Step 6: Document Everything

Before you finalize a sale or recycling transaction, make sure you have documentation ready. This includes:

- Model and serial numbers

- Ownership records or proof of purchase

- Condition reports

- Photos for reference

- Any service or maintenance records

Clear documentation helps build trust with buyers and ensures a smoother, faster transaction process. It can also protect you legally when equipment is resold or repurposed.

Bonus Tip: Stay Updated on Scrap Prices

Just like any commodity, scrap prices fluctuate based on global supply and demand. Keeping track of scrap metal pricing — especially for high-value components like copper, aluminum, and stainless steel — can help you decide the best time to sell.

Working with professional industrial scrap buyers can give you real-time updates and better pricing compared to generalized dealers or middlemen.

Final Thoughts: Resell, Reuse, or Recycle?

Ultimately, evaluating industrial equipment for resale requires balancing functionality, demand, and material value. In many cases, if resale isn’t viable, industrial equipment recycling becomes the most efficient and profitable solution.

Not only do you recover value, but you also contribute to environmental sustainability by keeping heavy materials out of landfills. With the right evaluation, logistics, and partners in place, your outdated equipment might be worth more than you think.

Need help getting started? Connect with experts in industrial scrap metal, scrap equipment buyers, or transformer dismantling to get fast, fair evaluations and responsible recycling solutions.