Demolition today is no longer just about wrecking balls and bulldozers—it’s a high-tech process that combines precision, safety, and sustainability. As industries evolve and outdated facilities are dismantled, the focus has shifted towards smarter, cleaner, and greener methods. One of the driving forces behind this change is the innovative use of industrial recycling equipment, which is transforming how demolition projects are planned and executed.

The Shift Towards Technology-Driven Demolition

In the past, demolition projects generated large amounts of waste with minimal concern for environmental impact. But now, industries demand solutions that are not only effective but also eco-conscious. Thanks to modern industrial recycling equipment, demolition no longer means destruction—it means opportunity.

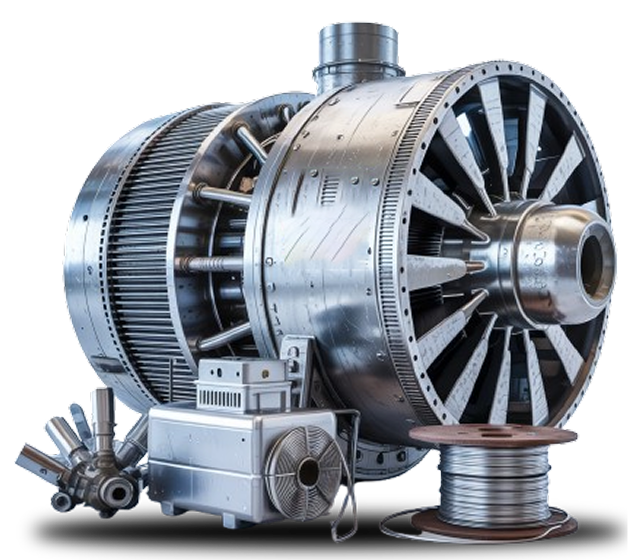

Advanced tools and robotics are now used to precisely cut, sort, and process materials. These machines can identify valuable components and separate them from debris, helping companies recover metals, electronics, and even old infrastructure parts for reuse or resale. This shift not only reduces landfill waste but also saves money and energy.

Precision with Robotics and AI

Robotics and artificial intelligence have made a big impact on the demolition sector. Smart machines can now carry out selective demolition—removing specific parts of a building while leaving others untouched. These robots use real-time data and sensors to operate in confined or dangerous spaces, minimizing the risk to human workers.

Additionally, AI helps analyze building materials before demolition begins. This analysis identifies valuable materials like copper wiring, steel beams, and transformers that can be recycled using industrial recycling equipment. This technology-driven insight increases both the efficiency and profitability of demolition projects.

Integration with Industrial Scrap Processes

Modern demolition projects are closely linked with the industrial scrap metal industry. Materials salvaged from demolition sites—like transformers, turbines, and electrical equipment—are now systematically processed and repurposed. Companies specializing in industrial recycling play a vital role in ensuring that these materials are handled responsibly.

For example, transformer dismantling has become a specialized task. Instead of discarding massive metal units, companies extract and sort valuable components such as copper, aluminum, and insulation materials. These items are then fed into the industrial recycling equipment for processing, helping reduce the demand for newly mined metals and lowering the overall environmental footprint.

Enhancing Safety and Compliance

Technology doesn’t just make demolition smarter—it makes it safer. Drones and 3D scanning tools are now used to survey structures and create detailed models before demolition starts. This allows teams to plan with greater accuracy and avoid hazards.

Moreover, automated demolition disposal systems reduce the risks associated with manual material handling. For example, heavy metals, toxic substances, or unstable structures can be identified and dealt with using remote-operated machines, minimizing human exposure.

Compliance is another area improved by technology. Environmental regulations now require proper handling of hazardous waste and recyclable materials. With the use of industrial recycling equipment, companies can easily track, sort, and report waste streams to stay compliant with local and federal guidelines.

Connecting with the Recycling Supply Chain

Modern demolition isn’t complete without connecting to the broader scrap recycling industries. Companies no longer view scrap as leftover waste; instead, it’s a resource with real market value. From scrap wire to industrial scrap metal recycling, every bit counts.

Leading scrap equipment buyers now work directly with demolition firms to collect valuable salvage materials. This partnership allows smoother logistics and better pricing for both parties. In turn, these materials are sent for refining, resale, or repurposing, giving them a second life in new infrastructure, vehicles, and equipment.

Environmental and Economic Benefits

The environmental benefits of using high-grade industrial recycling equipment are significant. Reusing metals and components reduces the need for new mining operations, conserves energy, and lowers greenhouse gas emissions. But the benefits aren’t just ecological—they’re economical too.

Businesses can recover significant costs by selling salvaged materials through professional industrial scrap buyers. For example, materials like copper and aluminum from old transformers or power plant equipment can fetch high market prices when recycled properly.

Additionally, some companies specialize in transformer dismantling, offering competitive scrap transformer prices and safe, certified recycling processes. This creates a win-win for demolition firms and the environment alike.

The Future of Demolition and Recycling

As technology continues to evolve, the future of demolition looks even more promising. Automation, AI, and industrial recycling equipment will continue to reshape how we approach large-scale deconstruction projects.

We can expect more remote-controlled machines, improved waste-sorting technologies, and AI-driven recycling systems that can evaluate, sort, and process materials with greater precision. This evolution will make demolition safer, cleaner, and more profitable.

Final Thoughts

Technology is redefining the demolition industry, turning it from a brute-force task into a smart, sustainable process. At the heart of this transformation lies the power of industrial recycling equipment. From identifying valuable scrap to processing and repurposing it, these tools are the backbone of modern demolition.

As industries grow and infrastructure is upgraded, the need for efficient, eco-friendly demolition will only increase. And with it, the demand for reliable industrial recycling solutions will grow as well—ensuring that no valuable resource goes to waste.